Three Strategic Advantages SEVEN CORPORATE Delivers to ZTOS Company

As an ODM service provider with decades of deep expertise in HVAC and industrial automation, SEVEN CORPORATE injects core competitive advantages into ZTOS Company (hypothetically an Industrial IoT solutions provider) through its technical prowess, quality control, and supply chain agility. Below is an analysis of the collaborative value across three dimensions:

1. ODM Excellence: Accelerating Innovation and Execution in Industrial Automation

1.1 Seamless Conversion of Client Requests into Market-Ready Products

Deep Understanding of Client Needs: Leveraging its expertise in industrial scenarios, SEVEN CORPORATE swiftly transforms ZTOS’s client requirements (e.g., equipment interoperability, predictive maintenance, energy optimization) into mass-producible solutions. For example:

Developing smart controllers integrating vibration monitoring and temperature compensation for smart manufacturing lines.

Designing edge computing gateways supporting Modbus/TCP protocols for energy management systems.

Modular Development for Cost Efficiency: Standardized interfaces and scalable architectures reduce ZTOS’s R&D cycles by over 45% while cutting per-project development costs.

1.2 Leading Technological Frontiers

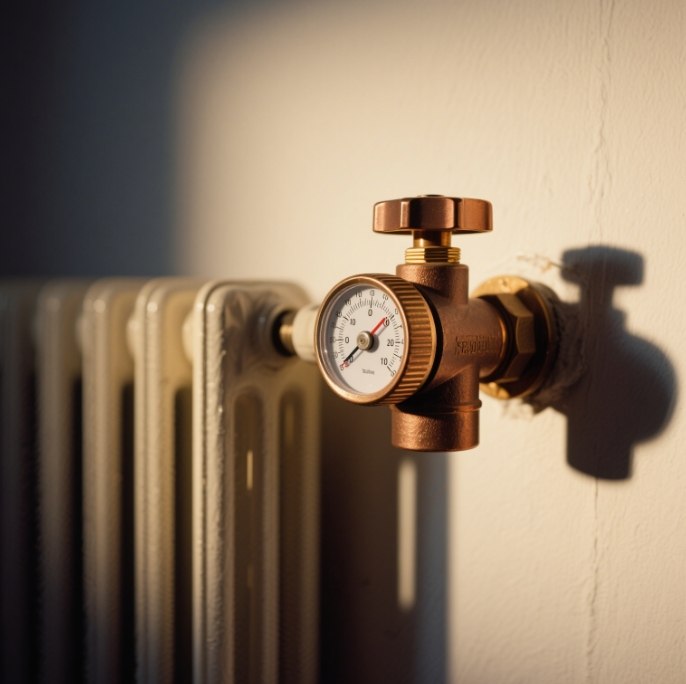

Industrial-Grade CustomizedThermostat Solutions: For ZTOS’s industrial temperature control systems, SEVEN CORPORATE engineered AI-driven thermostat modules with predictive fault diagnostics, enabling equipment health management and positioning ZTOS in the Industrial 4.0 market.

Trend Anticipation: Early adoption of TSN (Time-Sensitive Networking) standards helped ZTOS become a first-mover in deterministic networking devices.

2. Stringent QC Control: Building a Quality Moat for Industrial Products

2.1 End-to-End Quality Assurance

100% In-Process Testing: Every device undergoes EMC, thermal shock, and long-term stability testing to meet IEC industrial standards.

4-Hour Burn-In Testing: Simulated extreme industrial conditions (e.g., high vibration, dust exposure) ensure ZTOS products achieve a <0.2% failure rate over three years, far below industry averages.

2.2 Quality-Driven Premiumization

Brand Reputation Boost: Reliable performance has made ZTOS the preferred supplier for automotive manufacturing and semiconductor industries, increasing customer retention to 75%.

Cost Optimization: High yields reduce after-sales costs by 25%, freeing resources for advanced R&D.

3. Intelligent Supply Chain: Enabling Agile Delivery and Inventory Efficiency

3.1 ERP-Powered Supply Chain Synergy

Automated Replenishment and Scheduling: Real-time ERP integration with ZTOS synchronizes orders and materials, shortening procurement cycles by 40% and ensuring stable supply of industrial chips, sensors, and other critical components.

Automated Production Lines: Injection molding and SMT lines increase daily output by 3.5x, supporting ZTOS during urgent large-scale projects (e.g., smart factory deployments).

3.2 Flexible Production for Volatile Markets

Small-Batch Versatility: Modular lines enable quick switches between products of varying protocols and protection ratings, meeting ZTOS’s demand for customized Industrial IoT solutions.

Inventory Turnover Improvement: Precise demand forecasting reduced ZTOS’s inventory days from 60 to 35, enhancing capital efficiency.

Conclusion: From Efficiency Gains to Ecosystem Synergy

SEVEN CORPORATE delivers value to ZTOS beyond traditional supplier dynamics:

Short-Term Impact: Rapid delivery capabilities helped ZTOS secure multiple $10M+ industrial projects, driving 35% YoY revenue growth.

Long-Term Differentiation: Quality and innovation established ZTOS as an Industrial IoT leader, boosting valuation by 60%.

Ecosystem Collaboration: Joint development of predictive maintenance solutions is expanding into rail transit and port logistics, unlocking new growth avenues.

As SEVEN CORPORATE advances in carbon-neutral manufacturing and AI-driven quality control, ZTOS’s sustainability and competitiveness will further strengthen, redefining the future of industrial automation innovation.