Our products

More news content

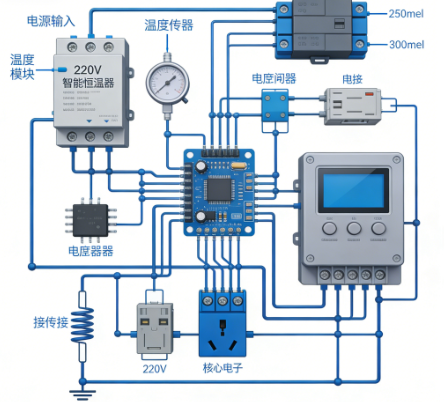

Are there high requirements for the wiring of a 220V smart thermostat?

220V smart thermostats are widely used in heating, electric heating, and temperature control systems. Their power supply is directly connected to common household or industrial voltages. Therefore, many users pay attention to whether special wiring configurations are required when selecting and installing them. Understanding the actual wiring requirements of a 220V smart thermostat helps maintain system stability during use and reduces potential problems caused by improper wiring.

Requirements for Basic Wiring Conditions under 220V Power Supply

220V smart thermostats are directly powered by AC, maintaining the same voltage level as conventional lighting or socket circuits. From a power supply perspective, they do not introduce additional high voltage or special power sources, so the basic wiring conditions are not unfamiliar. Under normal circumstances, household or equipment wiring that conforms to electrical codes can meet the basic power supply needs of the thermostat.

However, the thermostat needs to maintain continuous power during operation to achieve temperature acquisition, signal processing, and control output. This places certain requirements on the stability of the wiring. Excessive voltage fluctuations, poor contact, or aging wiring can all affect the normal operation of a thermostat. Therefore, the integrity and reliability of the wiring itself are crucial prerequisites for using a 220V intelligent thermostat.

The Impact of Load Characteristics on Wiring Capacity

220V intelligent thermostats typically have low power consumption, with their core functions focused on control and regulation rather than directly handling high-power loads. However, in actual systems, thermostats are often connected to heating equipment or other electrical loads via relays or control ports. In this case, the wiring needs to consider the power requirements of both the thermostat and the controlled equipment.

When the controlled equipment has high power, the current-carrying capacity and protection measures of the wiring become particularly critical. Wiring specifications, conductor cross-sectional area, and circuit breaker protection devices should all be matched to the overall load. Although the thermostat itself does not place stringent requirements on the wiring, the control system it is part of will affect the overall wiring design, which is a key aspect that users need to pay attention to during installation.

The Role of Wiring Standards in Ensuring Operational Safety

220V intelligent thermostats are directly connected to mains power, and their wiring method must comply with electrical safety regulations. Correctly distinguishing between live wires, neutral wires, and control ports is fundamental to ensuring stable equipment operation. Clear and secure wiring effectively reduces contact resistance and the risk of overheating.

Simultaneously, a reasonable wiring layout helps reduce electromagnetic interference, resulting in more stable temperature signal acquisition. Proper wiring not only affects the lifespan of the thermostat itself but also the safety of the entire temperature control system. Under the premise of meeting basic wiring requirements, following standardized operating procedures will fully leverage the performance advantages of the 220V intelligent thermostat.

Conclusion

The 220V intelligent thermostat maintains the same voltage level as conventional power environments, without imposing excessively high barriers to wiring. Its true focus lies in wiring stability, load matching, and wiring specifications. As long as the wiring conditions are reasonable and the installation method is standardized, the 220V intelligent thermostat can maintain stable operation in various application scenarios, providing reliable support for temperature control.