Our products

More news content

How to Reduce the Risk of Wiring Errors in Underfloor Heating Systems?

During underfloor heating installation, many people focus on pipe laying, main unit selection, and temperature control performance, often overlooking an “invisible but crucial” aspect—wiring. In fact, a large portion of problems in underfloor heating systems stem from wiring errors, such as thermostats malfunctioning, certain rooms not heating up, water pumps failing to start, or even frequent boiler start-stop cycles. These problems not only affect the user experience but also increase the cost of later troubleshooting and rework. Why are underfloor heating wiring errors so easy to make? The reason is simple: numerous lines, complex equipment, and scattered control points. Traditional underfloor heating systems typically have one thermostat corresponding to one set of circuits, with actuators, water pumps, and boilers wired separately. The cables on the construction site are crisscrossed, and it’s easy to make mistakes, omissions, or even reverse connections if not careful. For installers, the more complex the wiring method, the higher the probability of error. To truly reduce the risk of wiring errors in underfloor heating, a reasonable system design and centralized wiring method can simplify the complex process and fundamentally reduce human error.

Why are underfloor heating wiring errors so easy to make?

Many users only discover problems after installing or using underfloor heating, but wiring errors often sow the seeds of future problems during the construction phase. First, underfloor heating systems involve numerous devices, including thermostats, thermal actuators, circulation pumps, and boilers. Each additional device means an extra set of wiring. Second, traditional distributed wiring methods require connections at different locations, resulting in inconsistent wiring routes, unclear labeling, and easy confusion. Furthermore, if the control logic for different rooms and areas isn’t planned in advance, on-site adjustments to wiring significantly increase the probability of errors. The more complex the system and the more disorganized the site, the harder it is to avoid wiring errors.

Centralized Management

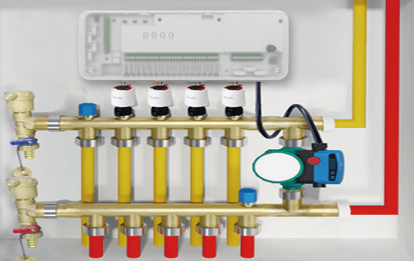

The first step in reducing the risk of wiring errors is to avoid “wiring everywhere.” Centralizing the previously scattered connection points into a unified wiring center is equivalent to establishing a “command center” for the entire underfloor heating system. All thermostat signals, actuator, pump, and boiler connections are completed from this center, resulting in clear wiring. Underfloor heating wiring centers like the HR-02 are designed to solve the problem of scattered wiring. As the central hub of the system, it allows installers to complete major wiring work in only one location, significantly reducing back-and-forth wiring and repetitive operations, naturally lowering the possibility of incorrect wiring.

Advance Zone Planning to Avoid On-Site Rewiring

Many wiring errors are not “technical problems,” but “planning problems.” If the number of zones and control methods for the underfloor heating are not clearly defined before installation, adjustments are easily made during construction, and even temporary rewiring may be necessary. Each change introduces a new risk. A wiring center supporting 8 or 16 zones offers a significant advantage in this regard. Whether it’s a small apartment or a commercial space with many rooms, zones can be planned in advance according to actual needs, allowing for one-time wiring completion and avoiding repeated dismantling and modification later.

Centralized Actuator Connection

In underfloor heating systems, the large number of thermal actuators and frequent wiring make it the most error-prone area. If actuators in each zone are wired separately, incorrect wiring can lead to the awkward situation of “one room controlling another.” Through the cabling center, each area’s actuators have clearly defined access ports, and a maximum of five thermal actuators can be connected to a single area, meeting practical needs without creating a cluttered appearance. During installation, simply align the area number for connection, significantly reducing the risk of incorrect area connections or actuator mixing.

Unified Output for Pumps and Boilers, Avoiding Linkage Errors

The circulating pump and boiler are the core power source of the underfloor heating system. Incorrect control signal connections can lead to anything from failure to start to shortening equipment lifespan. Traditional wiring methods often require separate handling for these components, increasing complexity. The cabling center provides dedicated output interfaces for the circulating pump and boiler, with all linkage mechanisms internally streamlined. Installers only need to follow the interface labels to ensure synchronized operation of all critical components, preventing system malfunctions caused by incorrect linkage connections.

Wireless Thermostat for Further Reduced Cabling Complexity

While wired thermostats are stable, they require significant wiring work and are more prone to errors. The cabling center, seamlessly integrated with wireless thermostats, significantly reduces the number of wiring runs and connection points within the walls. Replacing some physical wiring with wireless signals inherently reduces the probability of wiring errors and also makes the overall installation more flexible.

Ultimately, reducing the risk of wiring errors in underfloor heating isn’t about relying on experience to “tough it out,” but rather about reducing complexity through reasonable system design. The fewer and more centralized the wiring, the lower the chance of errors. Instead of repeatedly checking on-site, it’s better to choose a more scientific wiring method from the beginning. Underfloor heating wiring centers, such as the HR-02, use centralized wiring, clear zoning, dedicated outputs, and wireless collaboration to make the originally complex and error-prone underfloor heating wiring process orderly and controllable. This not only shortens installation time but also makes later maintenance and troubleshooting easier. Whether installing new underfloor heating or upgrading an existing system, choosing a suitable wiring center is a crucial step in reducing the risk of wiring errors and improving overall heating efficiency.