Our products

More news content

How to Simplify the Wiring Process of Heating Systems?

In modern homes and commercial buildings, heating systems have become an essential guarantee of living comfort. However, traditional heating system wiring is complex, with scattered lines, making installation difficult, time-consuming, labor-intensive, and prone to wiring errors, affecting the stable operation of the system. Many homes or small commercial establishments often experience extended construction periods and increased maintenance costs when installing underfloor heating or central heating due to unreasonable wiring layouts. This not only causes headaches for installers but also worries homeowners about potential malfunctions later on. In fact, through scientific planning and reasonable design of the wiring process, the entire installation process of the heating system can be greatly simplified, while improving the system’s safety and stability, ensuring that the heating is truly instant and operates smoothly.

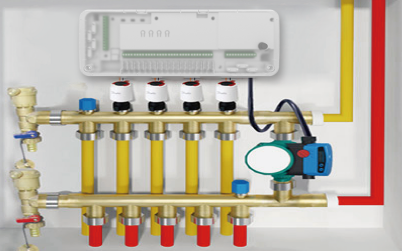

The core of simplifying heating system wiring lies in reducing line redundancy, centralized control, and intelligent management. Modern wiring methods are gradually shifting from traditional distributed wiring to centralized wiring centers, achieving centralized management of various heat sources, actuators, and thermostats through a unified hub. Compared to traditional methods, this centralized design not only makes construction clearer but also facilitates later maintenance and expansion. Meanwhile, choosing appropriate wiring paths and pipe routes can avoid wire crossings and tangles, reducing errors and safety hazards during construction. Most importantly, intelligently integrating wiring with the temperature control system allows for more precise temperature control in each area, improving energy efficiency and simplifying operation, eliminating the need for frequent manual adjustments by homeowners.

Advantages of Centralized Wiring Centers

Centralized wiring centers are key to simplifying wiring in modern heating systems. By connecting the boiler, circulating pump, thermostat, and various zone actuators to a central node, wiring becomes clear and controllable. Construction workers can directly lay unified lines from the central node to each area, avoiding the chaos of traditional multi-point wiring. This not only reduces construction time but also lowers the risk of malfunctions due to wiring errors. Furthermore, centralized wiring centers are typically equipped with labeling systems and standardized interface designs, facilitating future inspections and upgrades, making maintenance as simple as “changing a socket.”

Properly Planned Wiring Routes

Besides centralized wiring, properly planning the wiring route is also crucial for simplifying the wiring process. Before wiring, the pipe route should be determined based on the building layout and room functions, reserving pipe trenches along walls, floors, or ceilings as much as possible to avoid unnecessary bends and crossings. For multi-story buildings, vertical shafts or centralized pipe shafts can be used to connect the heating systems of each floor in a unified manner, which is both aesthetically pleasing and safe. Planning the routing in advance can also reduce temporary adjustments during construction, significantly improving construction efficiency.

Intelligent Temperature Control and Zoning Management

Modern heating systems increasingly emphasize intelligence, achieving zoning management through the linkage of thermostats, actuators, and the wiring center. Each room can independently control its temperature according to actual needs, avoiding unnecessary energy waste. Intelligent temperature control systems can also be remotely operated via mobile phone or tablet, allowing homeowners to adjust the indoor temperature at any time without frequent operation of the control panel. The combination of intelligent wiring and zoning management not only simplifies the wiring layout but also enhances the user experience, making the “heating system” truly convenient, comfortable, and energy-efficient.

Using Standardized Components

To further simplify the wiring process, the selection of standardized, modular components is crucial. Standardized interfaces, prefabricated fittings, and modular control units make the installation process as simple as assembling building blocks, reducing construction difficulty and error rates. At the same time, this design facilitates future expansion or replacement of equipment without the need for rewiring. Whether it’s a small-scale residential underfloor heating system or a large commercial heating system, standardized components significantly reduce construction complexity, making the entire wiring process more efficient and safer.

Simplifying the wiring process for heating systems hinges on a centralized wiring center, rational route planning, intelligent control, and the comprehensive application of standardized components. These methods not only shorten the construction cycle and reduce costs but also improve system reliability and user experience. Homeowners no longer need to worry about complex piping and cumbersome operations, and installers can complete the installation more easily.