Our products

More news content

How many thermal actuators can an 8-zone control box connect to at most?

In an underfloor heating system, the temperature regulation and heating effect of each room largely depend on the coordination between the control box and the thermal actuators. The control box controls the thermal actuators to open and close the zone valves via output signals, thereby regulating the flow of hot water to each room and achieving precise temperature control. For residential or commercial settings, choosing the appropriate control box and configuring the number of thermal actuators directly affects system stability, comfort, and installation costs. The HR02 control box, as a high-performance product, supports multi-zone control and expandable actuator connections, providing users with flexible wiring solutions.

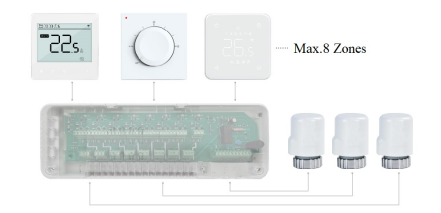

HR02 8-Zone Control Box Thermal Actuator Connection Rules

The HR02 control box is designed to support a maximum of 5 thermal actuators per zone. If a zone has multiple underfloor heating circuits, each circuit can connect to one actuator, and a maximum of 5 circuits can be directly controlled by a single port on the control box. However, in actual installation, the configuration should be based on the room area and the number of circuits, and should not exceed the port’s capacity; otherwise, relay overload or actuator malfunction may occur.

Total Number of Thermal Actuators Calculation

For an 8-zone control box, the total number of actuators = maximum number of actuators per zone × number of zones = 5 × 8 = a maximum of 40 thermal actuators. Even if the control box itself has 16 thermal actuator terminal interfaces, up to 40 actuators can be controlled through zone expansion modules or series connections. If the original number of terminals is exceeded, expansion modules or zone expansion boards provided by the manufacturer must be used to ensure safety and signal stability.

Single-Zone and Multi-Zone Wiring Strategies

If a room has multiple circuits, thermal actuators can be directly connected in parallel to the zone port, ensuring the total current does not exceed the port design. For multiple rooms, each room has one zone port, with a maximum of 5 actuators per zone, ensuring clear zone logic and easy future maintenance.

Installation and Configuration Precautions

Wiring Sequence and Terminal Assignment

Connect actuators according to zone number to avoid cross-wiring and ensure clear signals. Each wire length should be reasonable to avoid signal attenuation.

Power Supply and Load Matching

Each thermal actuator consumes a certain amount of power; the control box port has a maximum load limit. If this limit is exceeded, relay expansion is required. 3. Balanced Bus Power Distribution: Balanced power distribution is crucial to prevent single-port overload that could damage the control box or actuators.

Function Debugging: After installation, test the thermostats and actuators in each zone to ensure proper operation. Set boiler and pump delay times to ensure the system starts the heat source first, followed by the actuators in each zone, preventing pump idling or valve interference.

Expansion and Wireless Control: The HR02 control box supports wireless networks and Opentherm connections (optional). The number of controllers and actuators can be expanded via a smart platform to accommodate future upgrades. Wireless or digital interface expansion does not affect the original wired actuator limit of the 8-zone control box but provides remote monitoring and adjustment capabilities.

For the HR02 8-zone underfloor heating control box, each zone can connect up to 5 thermal actuators, for a total of 40 thermal actuators. This means that even multi-loop rooms or complex layouts can flexibly meet temperature control needs. During actual installation, attention must be paid to terminal allocation, power load, wiring length, and zone logic to ensure the stability and reliability of each line. Properly setting the boiler and water pump delay times, as well as individually debugging the thermal actuators in each zone, are crucial for ensuring system safety and heating efficiency. Through proper planning and configuration, not only can the control box’s capacity be maximized, but the difficulty of later maintenance can also be reduced, while leaving room for wireless network and Opentherm expansion.