Our products

More news content

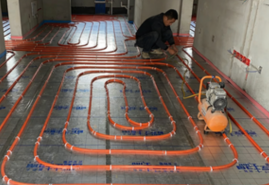

How to Lay Electrical Wiring for Underfloor Heating Systems?

With modern families’ pursuit of comfort and smart technology, underfloor heating systems have gradually become an important heating method for residential and office spaces. Besides pipe laying and heat source system design, electrical wiring is an indispensable part of underfloor heating system installation. Whether it’s electric or water-based underfloor heating, the wiring plays a crucial role in the control and execution of the system, directly affecting its safety, reliability, and long-term operation. Many users easily overlook the scientific nature of wiring during renovation, simply “running wires haphazardly” or mixing them with other wiring. This not only increases construction difficulty but may also lead to safety hazards such as leakage, short circuits, or difficulties in later maintenance. A reasonable wiring method can ensure smooth signal transmission between devices such as thermostats, actuators, circulation pumps, and boilers, and improve installation efficiency and system reliability.

Wiring Planning Principles

Before laying the underfloor heating wiring, it is necessary to clarify the principles of wiring planning. Wiring is not only a construction step but also involves the overall system design and safety management.

Clear Zoning: Underfloor heating systems are typically zoned by room or function, with each zone’s thermostats and actuators connected to a separate circuit. Clear zoning facilitates later maintenance and troubleshooting.

Centralized Management: A central wiring hub or control box is used to centrally manage wiring from all zones. Centralized wiring reduces on-site wiring clutter, improves construction efficiency, and lowers the risk of wiring errors.

Safety First: All wiring must comply with national electrical standards. High-temperature resistant and wear-resistant wires suitable for the load should be selected to ensure long-term safe operation and avoid safety issues caused by inferior wiring or improper installation.

Wiring Route Design

Wiring route design directly affects construction convenience and system reliability.

Separate Heat Sources and Control Lines: Power lines, thermostat signal lines, and other low-voltage wires should be laid separately to avoid signal interference and overload risks.

Follow the Shortest Path Principle: The wiring from the control box to each actuator, thermostat, and power supply should use the shortest possible path to reduce material waste and construction complexity.

Properly Secure Wiring: Wiring should be fixed along wall corners, pipe trenches, or pre-installed conduits to avoid being suspended in the air or crossing the ground, thus reducing the risk of damage and facilitating future maintenance.

Avoid Crossing Interference: When wires pass through walls or floors, avoid crossing or running parallel to other pipelines such as water pipes and gas pipes to reduce interference and potential hazards.

Wire Type Selection

The type of wire must be scientifically selected according to the different components of the underfloor heating system.

Separate High-Voltage and Low-Voltage Wires: Wiring controlling loads such as boilers and circulating pumps is typically high-voltage wiring, while thermostat signal lines and sensor lines are low-voltage wiring. High-voltage and low-voltage wires should be strictly separated and marked with different colors for easy identification.

High-Temperature Resistant Wires: Underfloor heating systems operate in high-temperature environments, especially in electric underfloor heating systems or wiring near heat sources. High-temperature resistant and aging-resistant wires must be selected to ensure long-term safe use.

Multi-Strand Flexible Wires: The connection wires between actuators and thermostats typically use multi-strand flexible wires for easy bending, laying, and maintenance.

Installation Precautions

During the actual wiring process, there are several key operational details to note.

Pipe Protection: When passing through floors or walls, protective conduits should be used to prevent wires from being scratched or crushed during construction or use.

Standardized Interface Treatment: All joints must be securely fixed and properly insulated and waterproofed to prevent loosening and leakage.

Clear Labeling: Each wire should be clearly labeled with its origin and purpose for easy maintenance and system expansion later.

Sufficient Maintenance Allowance: Leave an appropriate length of wire allowance during wiring to avoid rewiring for future replacements or maintenance.

Impact of Wiring on System Efficiency

Proper wiring not only ensures safety but also indirectly improves system operating efficiency. Centralized and standardized wiring reduces signal loss and the risk of poor contact, allowing thermostats and actuators to respond more promptly, ensuring precise temperature regulation of the underfloor heating system, thereby improving overall comfort and energy efficiency.

Underfloor heating wiring is a systematic project involving multiple stages, including planning, design, material selection, and construction. Scientific wiring methods should adhere to the principles of clear zoning, centralized management, and safety and reliability. This includes rationally designing wiring paths and selecting high-temperature resistant wires suitable for the load and environment. During construction, attention should be paid to secure wiring, standardized interfaces, clear labeling, and adequate maintenance allowances to ensure long-term stable system operation. Correct wiring not only improves construction efficiency and reduces installation errors but also enhances system response speed and heat distribution stability, allowing the underfloor heating system to achieve optimal comfort, reliability, and safety. Whether installing new underfloor heating or upgrading, mastering scientific wiring methods is a crucial prerequisite for efficient installation and long-term high-quality use.