Our products

More news content

How to Maintain a Long-Term Underfloor Heating Control Box?

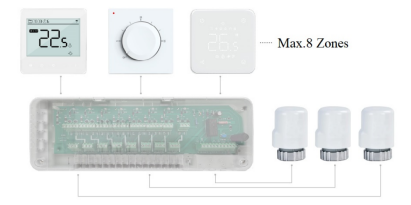

Underfloor heating systems are a core component of modern home heating, highly valued for their comfort and energy efficiency. The control box, acting as the “brain” of the system, is responsible for temperature regulation, circulation pump control, and zone management, making it a crucial component for ensuring the normal operation of the system. Without proper maintenance, long-term use of the control box can lead to problems such as aging wiring, damaged relays, and temperature control malfunctions, resulting in reduced heating efficiency and even impacting living comfort. Regular maintenance, rather than emergency repairs, extends equipment lifespan and reduces operating costs. Scientific maintenance methods not only reduce failure rates but also ensure stable and efficient operation of the underfloor heating system, allowing families to enjoy a warm and comfortable living environment during winter.

Daily Maintenance and Cleaning

Regular Power-Off Cleaning

After a period of use, dust and impurities easily accumulate on the circuit boards, ventilation holes, and relays. Long-term accumulation affects heat dissipation and increases the risk of component aging. It is recommended to clean the control box every 3-6 months by disconnecting the power. Use a dry, soft brush or air blower to remove dust, avoiding direct contact of a damp cloth with the circuitry.

Maintain Good Ventilation

Control boxes are typically installed in cabinets or walls. A closed, humid, or excessively hot environment will accelerate the aging of circuit components. Keeping the surrounding environment dry and well-ventilated can effectively extend the life of the control box and reduce the probability of temperature control malfunctions and relay burnout.

Check Displays and Indicator Lights

Regularly observe the display and indicator light status on the control box panel. If abnormal flickering or unclear display is found, promptly check whether the wiring or sensors are loose or aging.

Wiring and Connector Maintenance

Check Power Lines

During long-term use, power cords may become loose or have poor contact due to plugging and unplugging or vibration. Check the power cord connections every six months to ensure stable power supply to the control box and avoid damage to relays or circuit boards due to voltage fluctuations.

Zone and Temperature Control Wiring Inspection

In multi-zone underfloor heating systems, the temperature control lines and actuator lines for each zone also need to be checked regularly. Check for wear, breaks, or poor contact in the wiring. If necessary, use a multimeter to measure the continuity of the wiring to ensure accurate signal transmission.

Connector Maintenance

The pluggable connectors inside the control box are prone to oxidation or loosening, affecting current transmission. Contact protectant can be used, or regular plugging and unplugging and resetting can be performed to ensure stable circuit contact.

Component Function Testing and Prevention

Relay and Switch Inspection

Relays are crucial components controlling the circulating pump and zone valves. Long-term use may lead to contact erosion or poor engagement. Relays should be manually tested annually for proper engagement; if any abnormalities are found, they should be replaced promptly.

Temperature Sensor Calibration

Temperature sensors may experience temperature measurement deviations due to dust or aging over time. Regular calibration with a standard temperature reference source or replacement of the sensor can ensure accurate temperature control and prevent overheating or underheating of the underfloor heating.

Software and Program Maintenance

Some intelligent control boxes have program or timer functions. Long-term use requires regular checks of program settings and necessary software upgrades or resets to ensure accurate execution of control logic and heating strategies.

Maintaining the underfloor heating control box for long-term use is not only crucial for ensuring comfortable winter heating but also a key measure to extend system life and reduce maintenance costs. Regular cleaning, maintaining ventilation, and checking indicator lights and wiring connectors can effectively prevent most malfunctions. At the same time, periodically checking relays, temperature sensors, and control programs ensures accurate operation of the underfloor heating system, avoiding temperature deviations and equipment damage. Scientific and regular maintenance habits keep the underfloor heating control box stable and efficient over the long term, not only saving household expenses but also allowing family members to enjoy a warm and comfortable environment during cold winters.