Our products

More news content

Key Points for Selecting Fan Coil Thermostats in Engineering Projects

In large commercial buildings, office towers, hotels, and hospitals, fan coil systems (FCUs) are among the most common HVAC terminal units. The fan coil thermostat serves as the system’s core control component, and its selection directly affects indoor comfort, energy efficiency, and operational stability. Therefore, during the design and construction phases, engineering projects must carefully consider key factors when selecting thermostats to ensure efficient and reliable system performance.

Determine the Control Type Based on Project Requirements

Fan coil thermostats typically offer on/off control, three-speed fan control, or continuous modulation. Selection should consider project comfort requirements and budget:

On/Off Control: Simple and cost-effective, suitable for small or low-end projects, but provides limited comfort.

Three-Speed Fan Control: Allows low, medium, and high fan speeds, balancing cost and comfort; suitable for most office buildings and hotels.

Continuous Modulation: Provides precise fan speed and valve control, delivering the highest comfort; ideal for high-end buildings or specialized environments.

Match the Thermostat to the Fan Coil System Type

Engineering projects may use two-pipe or four-pipe FCU systems, and thermostat selection must match the system type:

Two-Pipe Systems: The thermostat mainly controls fan operation and valve on/off; simultaneous heating and cooling is not supported.

Four-Pipe Systems: Thermostats must control both heating and cooling valves to enable year-round temperature regulation, suitable for high-comfort applications.

Correct system matching ensures accurate temperature control and safe operation.

Consider Remote Control and Centralized Management

With the rise of smart buildings and Building Management Systems (BMS), many projects prefer thermostats that support remote control and centralized management:

Users can adjust temperature and fan speed remotely via mobile devices or control platforms, improving convenience.

Centralized monitoring allows facility managers to oversee multiple rooms or zones, optimize energy use, and streamline maintenance.

In large-scale projects, remote and centralized management is often a key selection criterion.

Material Quality and Durability

For long-term reliable operation, thermostat materials and manufacturing quality are critical:

Panels and housings should be heat-resistant, corrosion-resistant, and scratch-resistant.

Internal circuits and sensors must be highly reliable to ensure consistent temperature control over time.

Established brands with strong after-sales service can provide additional assurance for project longevity.

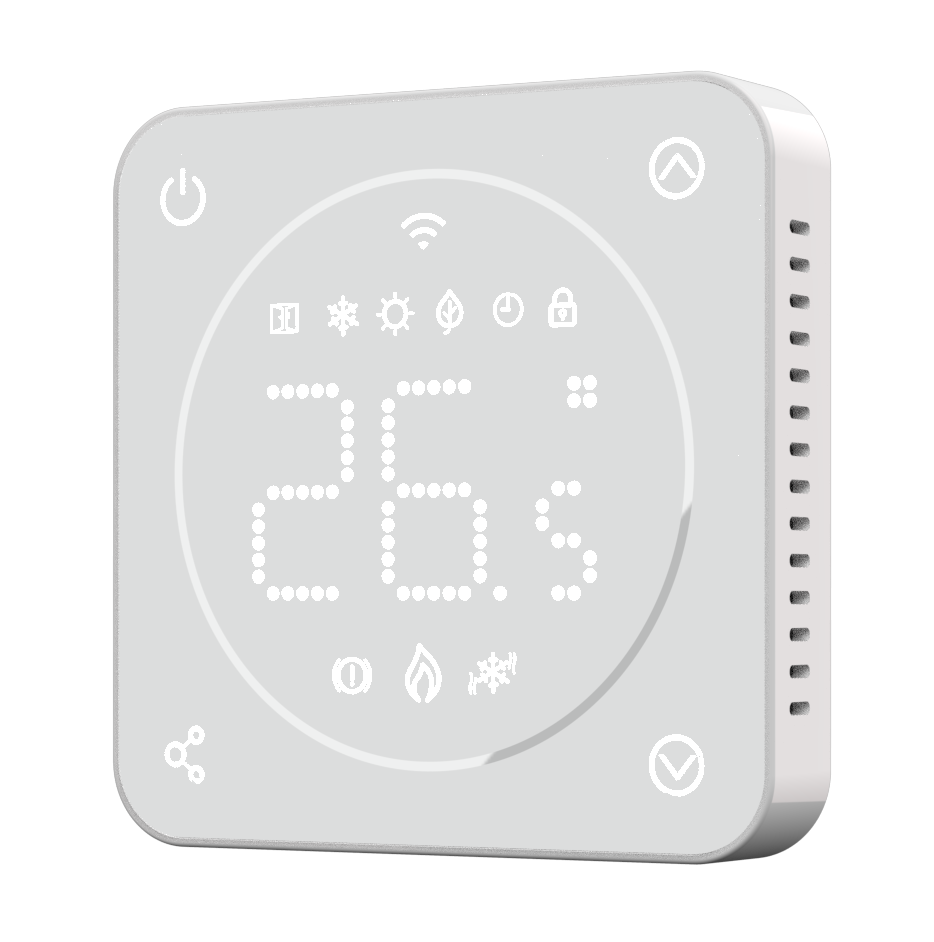

User-Friendliness and Experience

A well-designed interface and usability enhance operational experience:

Clear display and intuitive operation allow users and property managers to quickly adjust settings.

Features such as auto/manual switching and programmable schedules meet diverse usage scenarios.

Touchscreen or programmable models may be preferred for hotels or office spaces to improve user comfort.

Conclusion: Smart Selection Ensures Project Success

In engineering projects, selecting the right fan coil thermostat affects not only indoor comfort but also energy efficiency and system reliability. By considering control type, system compatibility, remote management, material quality, and usability, projects can achieve efficient, stable, and intelligent temperature control. Smart and informed thermostat selection is a key step in ensuring long-term FCU performance, improving building energy efficiency, and maximizing user satisfaction.