Our products

More news content

Optimal Configuration of Fan Coil Underfloor Heating Heat Pump Systems

Fan coil underfloor heating heat pump systems are widely used in modern buildings due to their high energy efficiency and comfort. The system relies on a heat pump as the primary heating and cooling source, with underfloor heating providing base temperature control and fan coil units offering rapid adjustments. An optimal configuration improves operational efficiency, extends equipment lifespan, reduces energy consumption, and ensures a comfortable indoor environment. Scientific system design and appropriate equipment selection are essential for achieving high performance.

Heat Pump Selection and Capacity Matching

The heat pump is the core component of the system and directly determines its heating and cooling capabilities. When selecting a heat pump, factors such as building area, floor height, insulation performance, and occupancy levels should be considered to calculate the required heating and cooling load. An undersized unit may result in insufficient heating or cooling, while an oversized unit can increase energy consumption and equipment wear. Efficiency ratings and modulation capabilities are also critical considerations, as high-efficiency models can significantly reduce operational costs.

Optimal Underfloor Heating Layout

Underfloor heating provides low-temperature radiant heat to ensure even indoor temperature distribution. Pipe spacing should follow design specifications to deliver stable heat output. Supply and return pipelines must be arranged to prevent uneven flow or localized temperature variations. Manifold placement should allow for easy adjustment and maintenance while ensuring that each loop achieves the designed flow rate. In large spaces, zoning can be applied to meet varying usage requirements in different areas.

Fan Coil Layout and Operation Optimization

Fan coil units perform rapid temperature adjustment, and their placement and operation directly affect comfort and energy efficiency:

Maintain proper spacing to ensure smooth airflow and prevent uneven heating or cooling

Ensure condensate pipe slopes meet standards to prevent water accumulation

Match fan speed with room size and occupancy for optimal performance

Reserve sufficient access space for maintenance and filter cleaning

Proper fan coil layout improves response speed and optimizes energy use.

Piping System and Hydraulic Design

The piping system connects the heat pump, underfloor heating, and fan coil units, with hydraulic balance being critical for stable operation. System design should plan manifold locations effectively, with valves and flow control devices enabling precise adjustment for each loop. Exposed pipes should be insulated to reduce heat loss. Pumps should be selected according to total system flow and loop resistance to maintain stable operating pressure and prevent insufficient flow in any section.

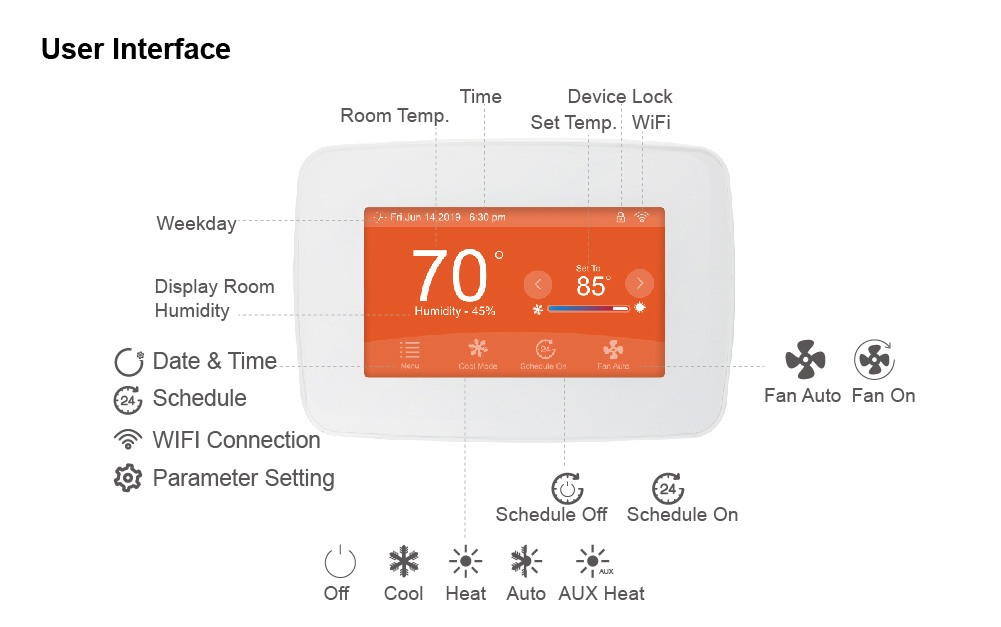

Control System Configuration and Smart Operation

Intelligent control systems enable zoned management for underfloor heating and fan coil units, optimizing system efficiency. Thermostats and actuators allow users to adjust temperatures in different areas according to actual use, balancing energy savings and comfort. The system should support scheduling, mode switching, and remote control to manage operations flexibly across seasons and time periods. Proper control strategies reduce frequent start-stop cycles and enhance overall system longevity.

Terminal Equipment and Environmental Adaptation

Terminal equipment selection should consider room function and environmental conditions. Bedrooms benefit from low-noise fan coil units, while public areas may require higher airflow to improve temperature response. Underfloor heating should be compatible with floor coverings to ensure efficient heat transfer. Matching terminal devices to environmental parameters maximizes system performance and enhances user comfort.