Our products

More news content

The underfloor heating has reached the set temperature, but the boiler keeps running?

Many users with underfloor heating systems have this question: the room is already warm, and the thermostat shows the set temperature, but the boiler is still running, making noise, and the indicator light is still on. After a while, it’s understandable to wonder: is there a problem with the system? Is something broken? Will it be very expensive to keep running like this? Actually, in most cases, the boiler continuing to run doesn’t necessarily mean there’s a malfunction. Underfloor heating systems don’t “stop and go” like traditional radiators; they involve the coordinated control of the thermostat, actuators, water pump, and boiler. If any link in the chain isn’t properly closed, the boiler will continue to run. This is especially true for underfloor heating systems with many rooms and circuits; without unified management, it’s easy to encounter situations where “the temperature is reached, but the boiler keeps running.”

Checking the Boiler Status of Only One Room

Many people judge whether the boiler should stop by only looking at their own room. However, in a multi-room underfloor heating system, as long as there is still one area requesting heat, the boiler will not stop. For example, if the living room is already warm, but the secondary bedroom, study, or bathroom hasn’t reached the set temperature, the system as a whole remains in a “heating needed” state. In this case, the boiler continuing to run is normal, not a sign of malfunction.

Lack of Unified Actuator Management

Multiple underfloor heating circuits mean multiple actuators. If these actuators are controlled separately and lack centralized management, some circuits may be closed while others remain open. If even one actuator isn’t completely shut down, the system will continuously send demand signals to the boiler, preventing it from shutting down. This problem isn’t necessarily due to a faulty actuator, but rather a lack of clear control logic.

Pump and Boiler Asynchrony

In many systems, the pump and boiler are controlled separately. Even if the boiler has stopped heating, the pump may continue running for a period to equalize the temperature. From the user’s perspective, hearing the equipment running might lead them to believe the boiler is still burning. However, it could simply be the pump circulating water. This situation is more prone to misunderstanding when there’s a lack of unified, coordinated management.

Lack of Centralized Control Management

When a floor heating system involves multiple thermostats and actuators, without a dedicated control center to coordinate the boiler, pumps, and the needs of each area, the following problems can easily arise: some areas may meet their needs but fail to provide timely feedback to the boiler; signals may be duplicated or delayed in some areas; the boiler may frequently start and stop or run for extended periods. All of these can lead to the phenomenon of “the temperature has been reached, but the boiler continues to run.”

How to Improve the Problem of Uninterrupted Boiler Operation

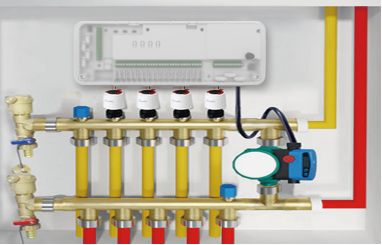

Device like the HR02C floor heating wired control box is designed to solve the problem of chaotic multi-zone management.It can: control up to 8 room thermostats, unifying and aggregating dispersed needs; manage up to 5 thermal actuators per zone, ensuring synchronized start-up or shutdown of circuits within the same zone; centrally manage the boiler and pumps, deciding whether to operate based on actual needs; provide clearer wiring and installation, reducing misjudgments caused by wiring errors; and support Modbus and Opentherm (optional), allowing for more precise boiler control and better matching with the characteristics of floor heating. Once the temperature control needs of all zones are uniformly determined, the boiler can truly “stop” when it should.

Impact of Management Methods

A boiler running continuously not only causes anxiety but can also lead to additional energy consumption and equipment wear. Centralized regional management allows the system to more accurately determine “whether heating is truly needed,” reducing unnecessary operation and making underfloor heating both comfortable and worry-free. Often, when the boiler continues to run after the underfloor heating temperature is reached, it’s not due to equipment failure but rather an unreasonable system management method. With many rooms, circuits, and actuators, a lack of unified coordination can easily cause the boiler to receive continuous heating signals, resulting in “not stopping when it should.”

By introducing centralized management devices like the HR02C 8-zone underfloor heating wired control box, the thermostats, actuators, water pumps, and boiler are uniformly scheduled, making system operation much clearer. It’s immediately clear which areas truly need heating and which have already met their needs, preventing the boiler from running unnecessarily. If the boiler continues to run unnecessarily next time, don’t rush to question the quality; check if the system lacks a reliable “manager.” When management is in place, the underfloor heating system can truly achieve—heating when it should heat and stopping when it should stop.